E-mail:sales@tmcut.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

TE-2025

TIMING

Product DescriptionTE series is TIMING’s high-ply cutting machine, an upgrade design based on TMCC series. The cutter designed with sand belt sharpener, 6000 RPM Driver, and a default setting of dynamic balance device is adopted, more faster and stable in performance. | Product Characteristics1. Sand belt sharpener 2. 6000rpm high frequency oscillation box 3. Ensures the precision 4. High efficiency and less lead time |

Max Cutting Height | 6cm / 9cm (after vac-sorb) |

Cutting Window | length (no limitation) |

width (no wider than the fabric width) | |

Working Width (Y) | 1700mm /2000mm/2200mm |

Normal Working Length (X) | 2500mm/3300mm optional |

Electricity | Three phase 380V, 30KVA,50~60Hz |

Power Consumption | 18KW max |

CAD&CAM Connect way | Ethernet communication / USB Flash memory |

Max speed of blade working | 6000rpm/min |

Compressed Air | 0.55Mpa 160L/min |

Cutting Speed | max.60000mm/min |

Acceleration | 0.8~1g (N/ Kg) |

Noise Level | < 75 dbA |

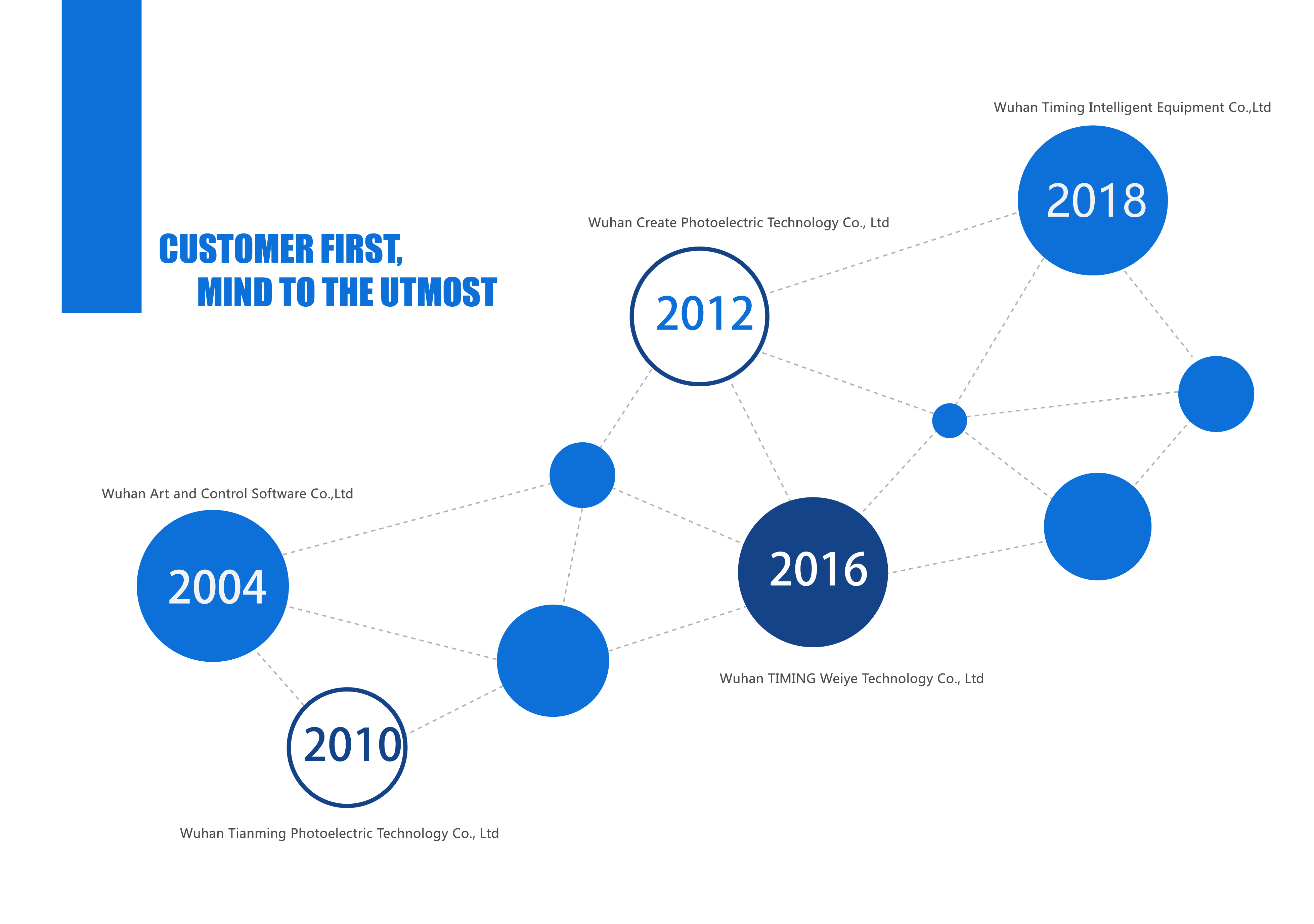

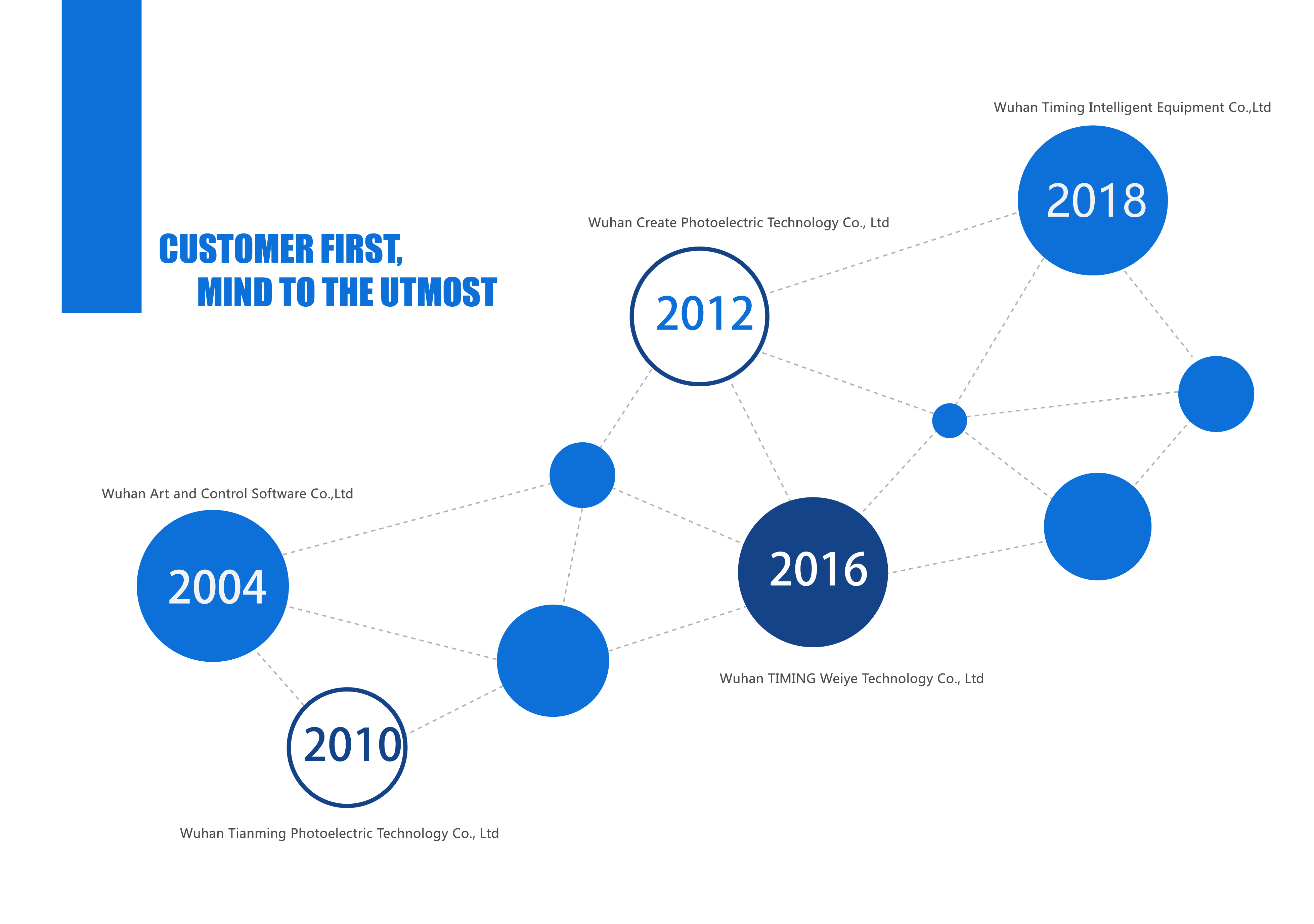

Wuhan TIMING Weiye Technology Co., Ltd

TIMING is an up-to-date industrial company, founded in 2012, constantly oriented to the new technologies and able to provide the cutting system for companies manufacturing apparel, technical fabric and composites. Nowadays, the main products we are manufacturing includes fabric automatic cutting machines,spreading machines, oscillating knife cutting machines, laser cutting machines and etc. With more than 100 employees, 3000 square meters workshop, TIMING factory with auto cutter production capacity at 100 sets monthly.

TIMING not only supplies machines, but it is the best technological partner, helping the customer to solve the cutting and spreading problem in production. Able to install all over the world more than 1500 units among cutting machine, spreading machines and etc.

Now in our sixteenth year, our vision is to become the first choice provider of intelligent cutting solutions; by investing in our people and continuing to improve our skills within our field of expertise, we will be known for our commitment to accuracy, quality and sustainability for the benefit of our clients.

1. Phone Support for solving problems.

2. Remote Support provided by our consultants through the Internet by means of the Team Viewer program.

3. ON-Site Support in abroad.

4. Sample Free Testing. We offer samples free testing according to clients requirements on processing before selling. So that we offer you the best machine and solutions.

5. Free Training. We provide clients with relative free training on operation and maintenancotally controlling it.

Product DescriptionTE series is TIMING’s high-ply cutting machine, an upgrade design based on TMCC series. The cutter designed with sand belt sharpener, 6000 RPM Driver, and a default setting of dynamic balance device is adopted, more faster and stable in performance. | Product Characteristics1. Sand belt sharpener 2. 6000rpm high frequency oscillation box 3. Ensures the precision 4. High efficiency and less lead time |

Max Cutting Height | 6cm / 9cm (after vac-sorb) |

Cutting Window | length (no limitation) |

width (no wider than the fabric width) | |

Working Width (Y) | 1700mm /2000mm/2200mm |

Normal Working Length (X) | 2500mm/3300mm optional |

Electricity | Three phase 380V, 30KVA,50~60Hz |

Power Consumption | 18KW max |

CAD&CAM Connect way | Ethernet communication / USB Flash memory |

Max speed of blade working | 6000rpm/min |

Compressed Air | 0.55Mpa 160L/min |

Cutting Speed | max.60000mm/min |

Acceleration | 0.8~1g (N/ Kg) |

Noise Level | < 75 dbA |

Wuhan TIMING Weiye Technology Co., Ltd

TIMING is an up-to-date industrial company, founded in 2012, constantly oriented to the new technologies and able to provide the cutting system for companies manufacturing apparel, technical fabric and composites. Nowadays, the main products we are manufacturing includes fabric automatic cutting machines,spreading machines, oscillating knife cutting machines, laser cutting machines and etc. With more than 100 employees, 3000 square meters workshop, TIMING factory with auto cutter production capacity at 100 sets monthly.

TIMING not only supplies machines, but it is the best technological partner, helping the customer to solve the cutting and spreading problem in production. Able to install all over the world more than 1500 units among cutting machine, spreading machines and etc.

Now in our sixteenth year, our vision is to become the first choice provider of intelligent cutting solutions; by investing in our people and continuing to improve our skills within our field of expertise, we will be known for our commitment to accuracy, quality and sustainability for the benefit of our clients.

1. Phone Support for solving problems.

2. Remote Support provided by our consultants through the Internet by means of the Team Viewer program.

3. ON-Site Support in abroad.

4. Sample Free Testing. We offer samples free testing according to clients requirements on processing before selling. So that we offer you the best machine and solutions.

5. Free Training. We provide clients with relative free training on operation and maintenancotally controlling it.